- SOLIDWORKS FLOW SIMULATION MOTION HOW TO

- SOLIDWORKS FLOW SIMULATION MOTION INSTALL

- SOLIDWORKS FLOW SIMULATION MOTION ZIP FILE

- SOLIDWORKS FLOW SIMULATION MOTION FULL

- SOLIDWORKS FLOW SIMULATION MOTION SOFTWARE

I suspect Dassault Systèmes doesn't support SolidWorks running in a virtual machine, particularly the free education version. An effective solution that balances performance and cost is to purchase a smaller SSD (~256 GB) for the operating system and installed programs and a traditional 7200 RPM drive for bulk storage. ) Program Files – The application (without this the program will not run). SolidWorks is currently used by over 2 million engineers and designers at more than 165,000 companies worldwide.

SOLIDWORKS FLOW SIMULATION MOTION ZIP FILE

zip file before the installation files are extracted.

Solutions: On Windows XP: Ensure your Windows User Account in Control Panel has 'Administrator' access right.

SOLIDWORKS FLOW SIMULATION MOTION SOFTWARE

SolidWorks is a CAD (computer-aided design) software application.

SOLIDWORKS FLOW SIMULATION MOTION HOW TO

Learn how to fix these Solidworks runtime errors quickly and easily! startup or shutdown, or during the Windows installation process. Program Data – The data (without it SolidWorks is a CAD (computer-aided design) software application.

SOLIDWORKS FLOW SIMULATION MOTION INSTALL

SOLIDWORKS FLOW SIMULATION MOTION FULL

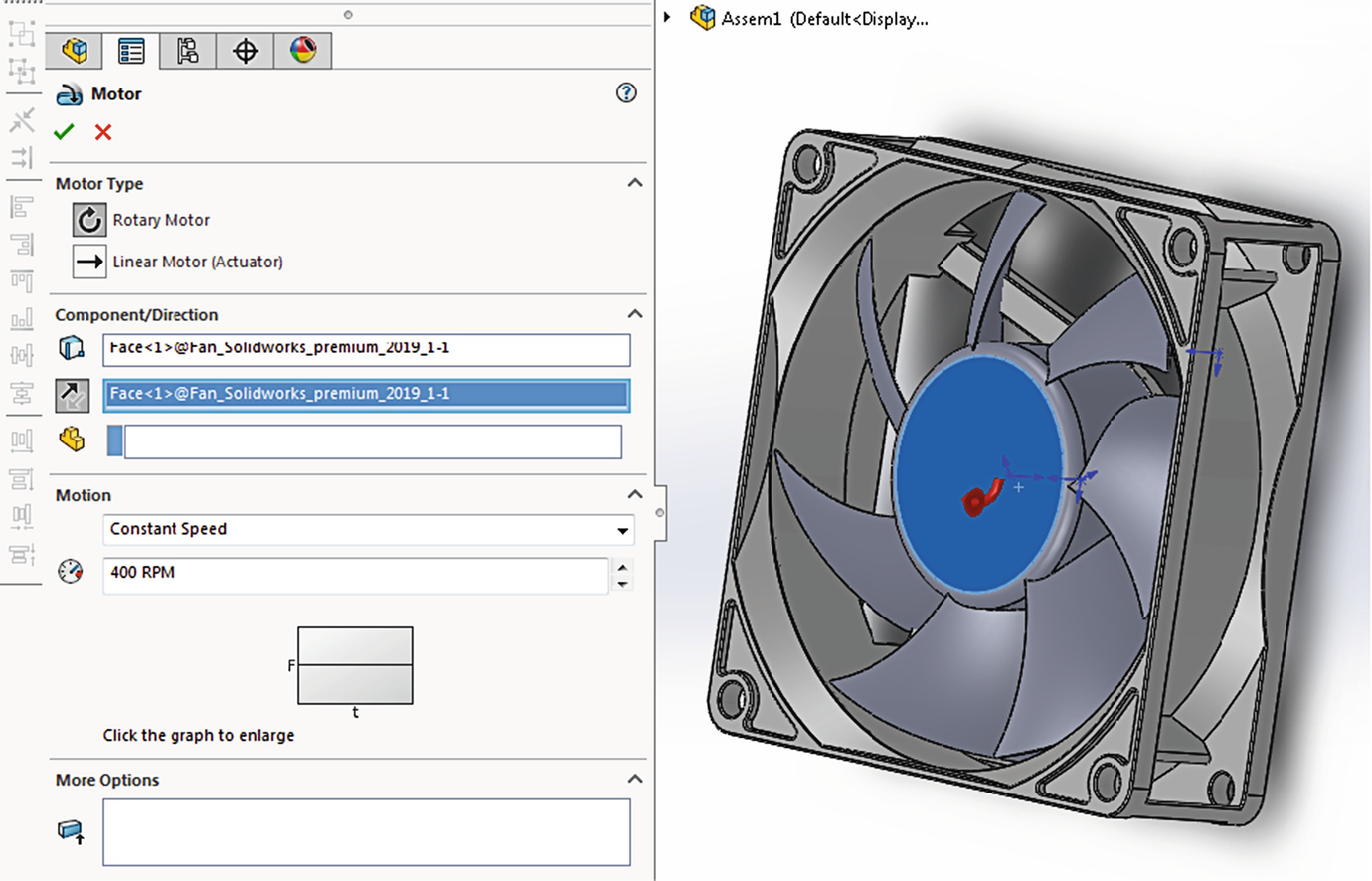

If you would like to access the complete results of each design point, make sure to activate the ‘Save full results’ option for the desired Design Point.įor our example, we ran 24 Design Points and can compare the maximum temperature of the chip easily in the table.Įach Design Point (meaning each scenario) can be saved as a new project so you can review the best scenario in detail with all the post processing tools of SolidWorks Flow Simulation.Īre you ready to test dozens of design ideas with CFD insight? Try the Parametric Study in SolidWorks Flow Simulation today and find your best design easily.Solidworks installation error windows 10

Once the Parametric study is run, you obtain the value of your output parameter, and your point of interest.

You can easily add a Design Point, or suppress one which might not be relevant to your product.

In SolidWorks Simulation, our users know well the tool called “Design Study.”ĭid you know that the same method is available for CFD with SolidWorks Flow Simulation? The tool is called “Parametric study.” This is an incredible productive tool which enables you to perform a set of CFD calculations with variation of CAD geometry and CFD conditions. A known value of CAD integrated simulation is to run “what if” scenarios as early as possible to find the best design and/or the design which fits your criteria.

0 kommentar(er)

0 kommentar(er)